Spectrophotometer CM-36dG color and gloss measurement

Another Yet Powerful Benchtop Spectrophotometer With State Of the Art Design

The CM-36dG is a high-precision spectrophotometer developed by Konica Minolta. It is commonly used in color management applications such as color matching, quality control, and product development.

Konica Minolta CM-36dG spectrophotometer is a successor to CM-3600A. It is built with horizontal alignment and has the same performance to its successor with higher precision. CM-36dG design is more compact, lighter in weight and with outstanding performance. It also comes with a UV adjustment function and is ideal for a wide range of applications such as pulp, paper, textiles, chemicals, etc.

Spectrophotometer CM-36dG is a highly accurate and repeatable benchtop color measurement instrument that comes with advanced functions for today’s measurement needs. CM-36dG is an advanced model offers both color and gloss result in a single measurement.

The CM-36dG features a spectral range of 360 to 740 nm and a spectral interval of 10 nm. It is capable of measuring both reflectance and transmittance of various types of samples including textiles, plastics, coatings, and liquids. The instrument has a high level of inter-instrument agreement, which means that different CM-36dG spectrophotometers will provide consistent color measurements.

In addition, the CM-36dG is equipped with new features to enhance usability. It features an easy-to-read status panel (Fig. 1.0) , with the measuring button located on it, that displays the measurement status and condition settings to minimize operator error and improve work efficiency.

Fig. 1.0

Fig. 1.0  Fig. 2.0

Fig. 2.0

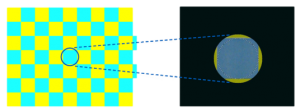

The sample viewing function (Fig. 2.0), utilizing an integrated camera, is also available to ensure accurate and easy positioning of the measurement sample.

The CM-36dG can measure color in either reflectance or transmittance mode. With a large and open-sided transmission chamber (Fig. 3.0), the CM-36dG can easily measure transparent or translucent samples of any sizes.

Fig 3.0

Fig 3.0  Fig. 4.0

Fig. 4.0

With a flat-back design, the orientation of CM-36dG can be repositioned to take measurements vertically (top-port concept) as shown in Fig. 4.0.

The CM-36dG offers high stability and reliability with its optional WAA*² (Wavelength Analysis & Adjustment) function. This innovative function analyzes and adjusts any wavelength shift during each calibration, ensuring the instrument and its measurement remain stable and reliable over time. Measurement operation usability has also been greatly improved over the previous models which will lead to increase operator productivity.

The CM-36dG also comes with four different aperture sizes (Ø 4.0 mm, 8.0 mm, 16.0 mm, and 25.4 mm), offering versatility to different measurement needs.

The instrument is controlled through software, which allows for easy measurement and analysis of color data. Contact us for a demonstration

APPLICATIONS:

Paint | Printing | Plastics | Ceramics | Textile | Packaging | PET Bottle | Food & Beverages etc.

*² WAA license required

Spectrophotometer CM-36dG

- 4 different measurement apertures Ø4mm, Ø8mm, Ø16mm and Ø25.4mm

- Measures reflectance only to accurately evaluate opacity of opaque and translucent solid sample.

- Tight inter-instrument agreement measures consistently with other instruments of the same model, allowing color values and specifications to be communicated, shared, and coordinated throughout the supply chain

- Wavelength Analysis & Adjustment (WAA) function²

- Conveniently measures SCE and SCI simultaneously for more consistent readings and to accommodate the surface conditions of each sample

- Excellent IMA (Inter Model Agreement) with CM-3600A series³

- Built with a footprint about the size of an average laptop computer to easily fit in small spaces

- Hand assembled with quality parts, making it durable and reliable to keep customer operations running as smooth as possible

- USB connection conveniently allows users to connect to a PC or laptop

- Conforms to international standards ie. CIE No.15(2004), ISO7724/1, ASTM E1164, DIN 5033 Teil7, and JIS Z8722 condition C standard.

- Integrates with SpectraMagic NX software for color quality control, as well as Colibri software for color formulation

*² Monitor and compensate wavelength shift due to external factor like daily temperature shift, aging etc. License required

*³For SCI (Specular Component Included) only

Spectrophotometer CM-36dG

| Color | Illumination/ Viewing System | Reflectance: |

| di:8°, de:8° (diffused illumination, 8° viewing), SCI (Specular Component Included) / SCE (Specular Component Excluded) switchable. | ||

| Conforms to CIE No.15, lSO7724/1, ASTM E1164, DIN 5033 Teil7, and JIS Z 8722 condition c standards | ||

| Transmittance: | ||

| di:0°, de:0° (diffused illumination, 0° viewing) | ||

| Conforms to CIE No.15, ASTM E1164, DIN 5033 Teil7, and JIS Z 8722 condition g standards | ||

| Integrating Sphere Size | Ø152 mm (6 inches) | |

| Detector | Dual 40-element silicon photodiode arrays | |

| Spectral Separation Device | Diffraction grating | |

| Wavelength Range | 360 to 740 nm | |

| Wavelength Pitch | 10 nm | |

| Half Bandwidth | approx. 10 nm | |

| Reflectance | 0 to 200% | |

| Range | Resolution: 0.01% | |

| Light Source | 3 Pulsed xenon lamps (2 with UV cut filters) | |

| Illumination / Measurement Area | LAV: Ø30.0 mm / Ø25.4 mm | |

| LMAV: Ø20.0 mm / Ø16.0 mm | ||

| MAV: Ø11.0 mm / Ø8.0 mm | ||

| SAV: Ø7.0 mm / Ø4.0 mm | ||

| Trans: Ø24.0 mm / Ø17.0 mm | ||

| Repeatability | Colorimetric values: Standard deviation within ΔE*ab 0.02 | |

| Spectral reflectance: Standard deviation within 0.1% | ||

| (When a white calibration plate is measured 30 times at 10-second intervals after white calibration) | ||

| Inter-Instrument Agreement | Within ΔE*ab 0.12 (Based on average for 12 BCRA Series II color tiles; LAV/SCI. Compared to values measured with master body under Konica Minolta standard measurement conditions) | |

| UV Setting | 100% / 0% / Adjusted | |

| Instantaneous numerical adjustment of UV with no mechanical filter movement required*1; 400 nm and 420 nm UV cutoff filters | ||

| Gloss | Measurement Angle | 60° |

| Light Source | White LED | |

| Detector | Silicon photodiode | |

| Measurement Range | 0 to 200 GU | |

| Resolution: 0.01 GU | ||

| Measurement Area | MAV (LAV/LMAV/MAV color measurement area): Ø10.0 x 8.0 mm ellipse | |

| SAV (SAV color measurement): Ø3.0 mm | ||

| Repeatability | 0 to 10 GU: within 0.1 GU | |

| 10 to 100 GU: within 0.2 GU | ||

| 100 to 200 GU: 0.2% | ||

| (When measured 30 times at 10-second intervals) | ||

| Inter-Instrument Agreement | 0 to 10 GU: ±0.2 GU | |

| 10 to 100 GU: ±0.5 GU | ||

| (MAV. Compared to values measured with master body under Konica Minolta standard conditions) | ||

| Geometry | JIS Z 8741 (MAV), JIS K 5600, ISO 2813, ISO 7668 (MAV), ASTM D523-08, ASTM D2457-13, and DIN 67530 | |

| Measurement Time | Approx. 3.5 second (SCI + SCE measurement) | |

| Approx. 4 second (SCI + SCE + Gloss measurement) | ||

| Minimum Interval Between Measurements | Approx. 4 second (SCI + SCE measurement) | |

| Approx. 4.5 second (SCI + SCE + Gloss measurement) | ||

| Sample Viewer Function | Using internal camera | |

| (Image viewable/copiable using optional software such as SpectraMagic NX software Ver. 3.2 or later) | ||

| Internal Performance Check*2 | WAA (Wavelength Analysis & Adjustment) Technology | |

| Interface | USB 2.0 | |

| Target Mask Auto Detection | Yes | |

| Power | Dedicated AC adapter | |

| Operating temperature / humidity range | 13 to 33°C, Relative humidity: 80% or less (at 35°C) with no condensation | |

| Storage temperature / humidity range | 0 to 40°C, Relative humidity: 80% or less (at 35°C) with no condensation | |

| Size (W x H x D) | Approx. 248 x 250 x 498 mm | |

| Weight | Approx. 8.4 kg | |

Specification is subjected to change without prior notice